Customer Requests: The fully automatic Brinell hardness testing of finished train wheels with the following specifications:

- Surface preparation and measurement of finished trainwheels - need to measure wheels of different diameters (from 700mm to 1300mm)

- Speed up the entire testing process

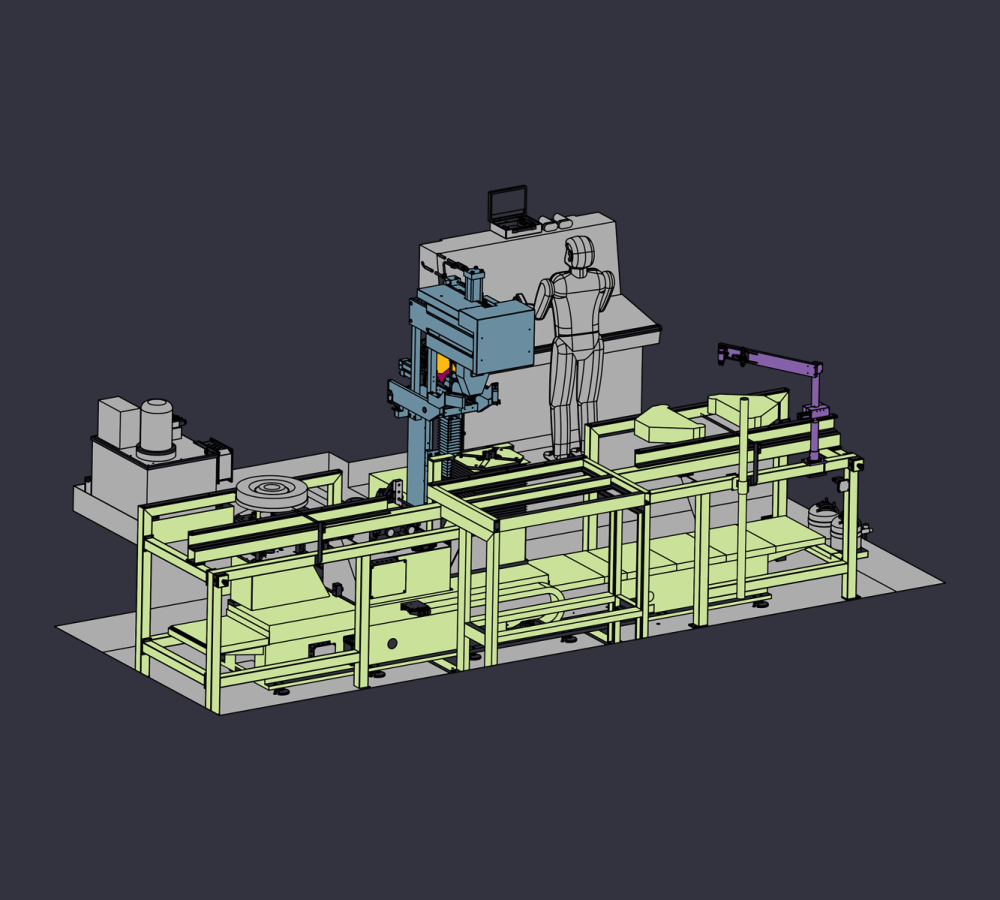

- Need to install into an existing production line consisting of machinery from other vendors

- Need to comply with specific regulations that require no. 2 measurements at a distance of 25mm from the first test if it is outside the range of hardness required

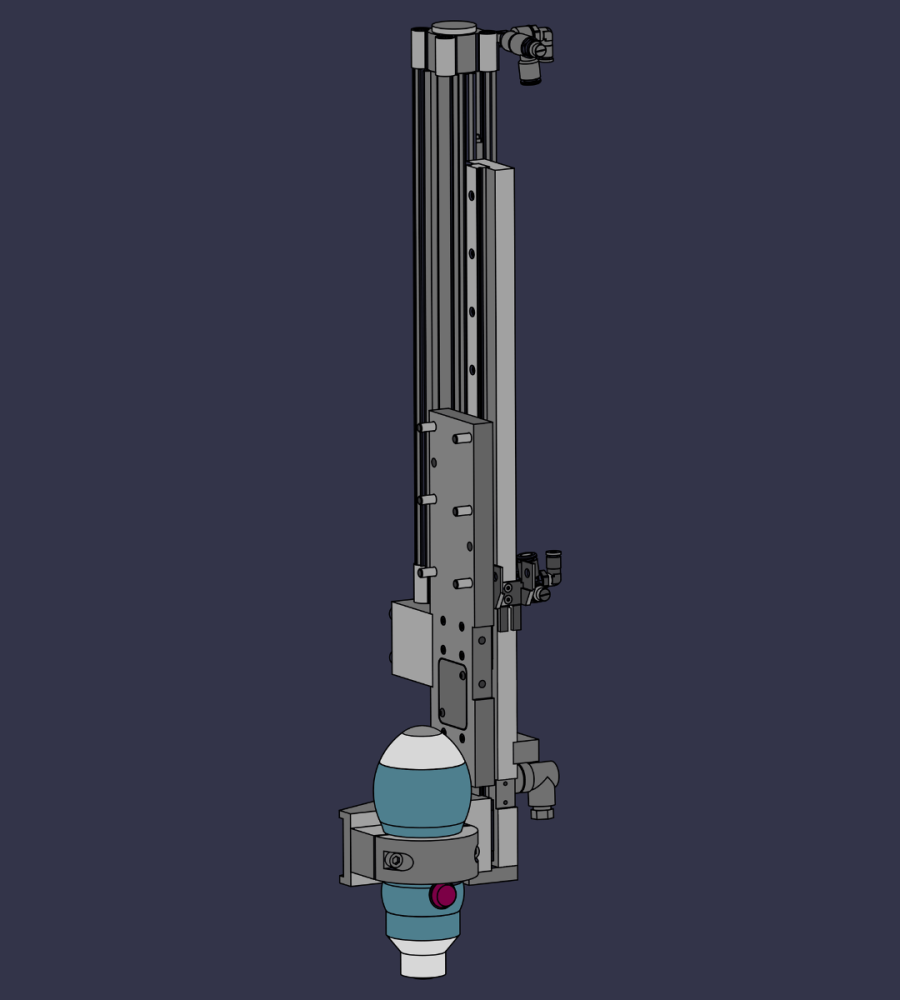

- Need to mark non-conforming wheels

Solution adopted

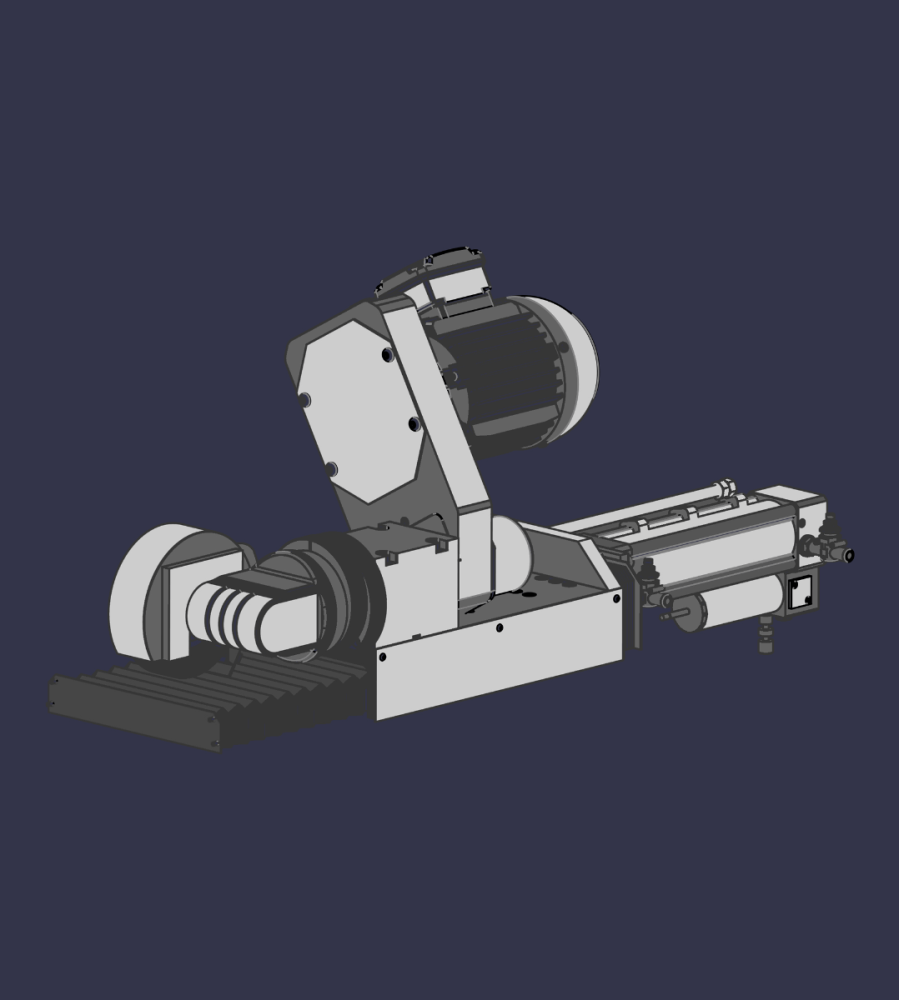

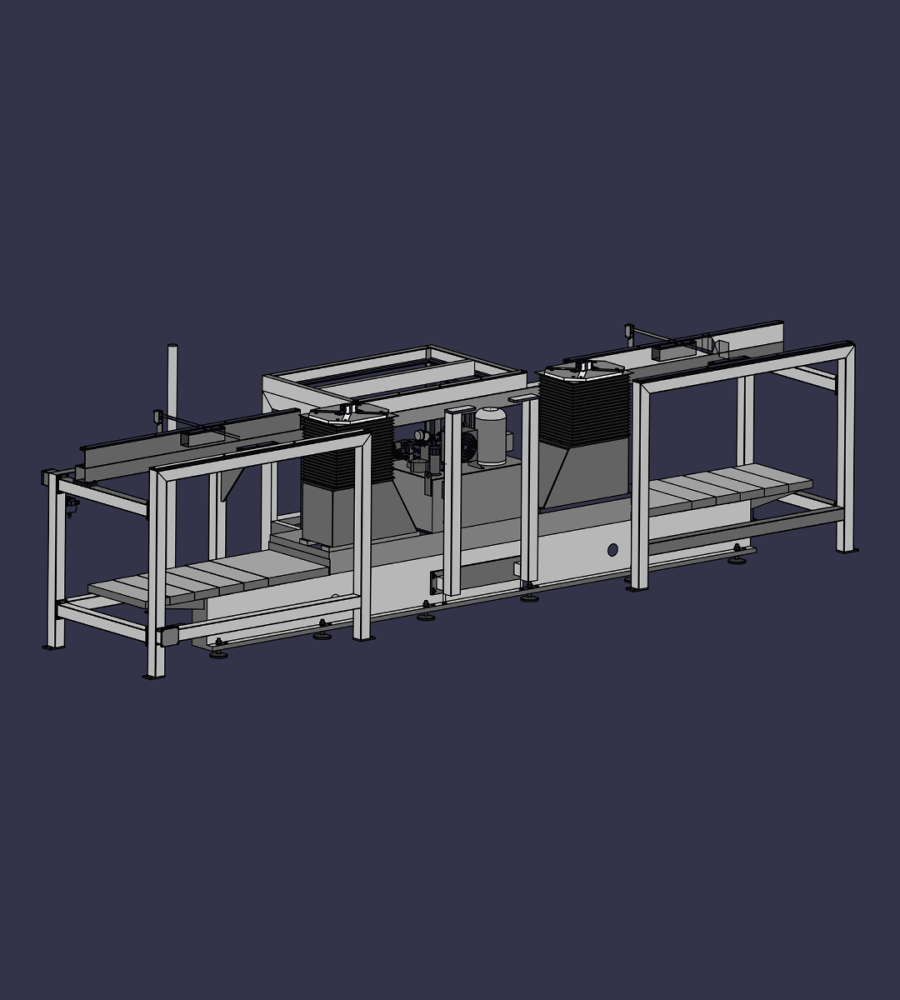

- Line equipped with lamellar wheel unit for surface preparation of finished wheels

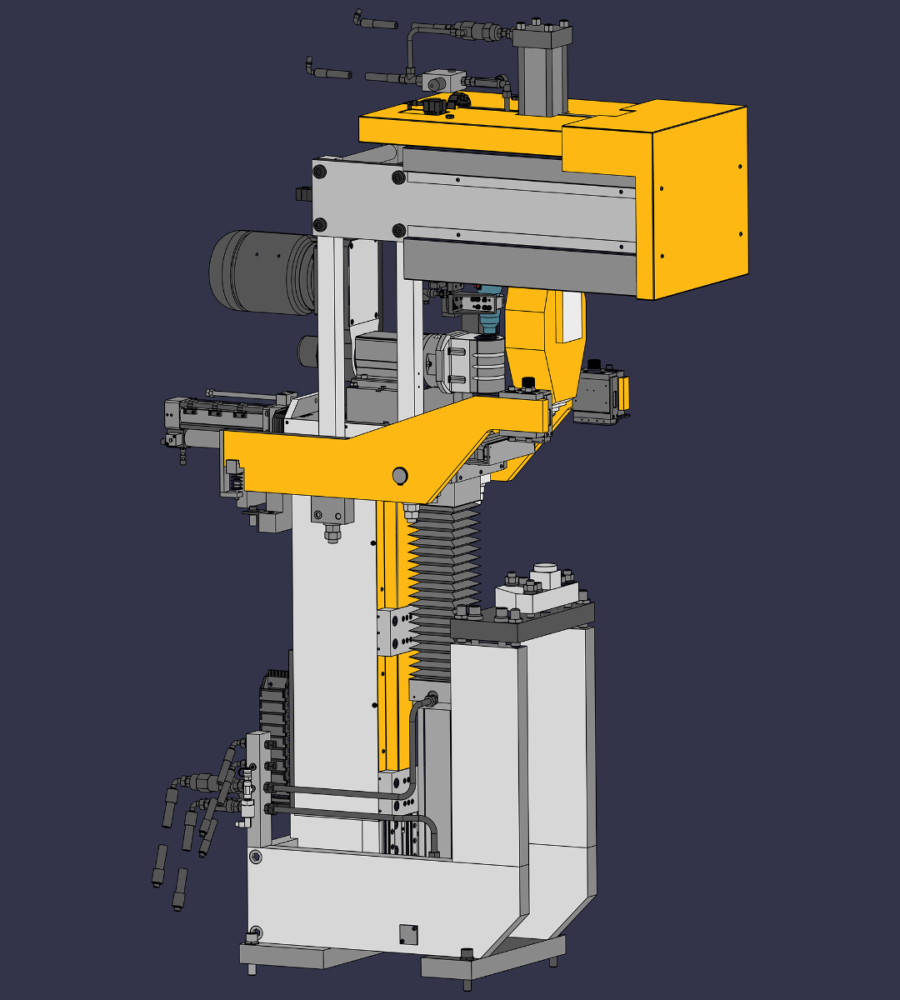

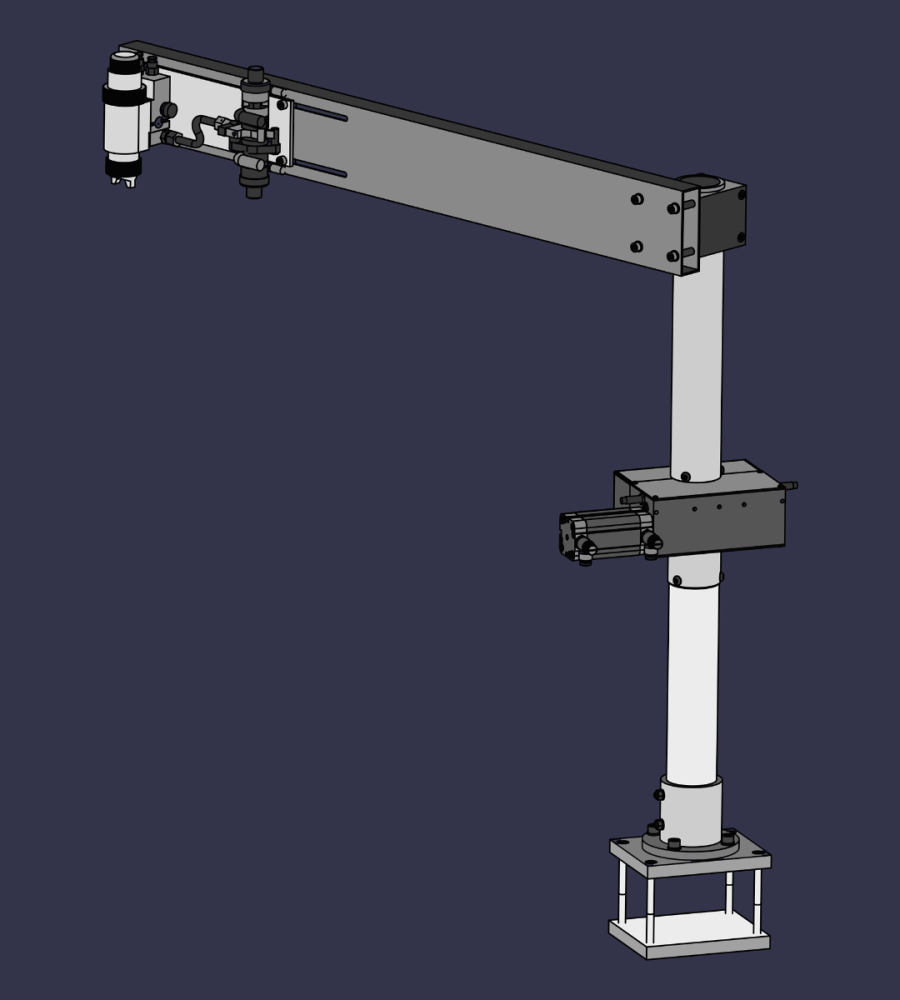

- Mounting of the entire hardness tester on a PLC-controlled motor-driven slide

- Creation of a transfer system that allows two wheels to be transported simultaneously from the loading point and the measuring point under the hardness tester to the unloading point

- Implementation of specific communication protocols for the exchange of signals and information with the PLC line controller

- Optimisation of the transfer system controls to allow the wheel to be moved for additional measurement positions. If the first test falls within the specified range, the wheel is transferred to the unloading position and at the same time a new wheel is brought from the loading position to the surface preparation and measurement position to be measured. If the first test is outside the set range, it will be automatically moved by 25mm and a second and third test will be carried out. If both these tests give a positive result, the wheel will result compliant

- If any of the above conditions do not occur, the wheel will be considered non-compliant and consequently marked with the spray paint unit located at the discharge position.